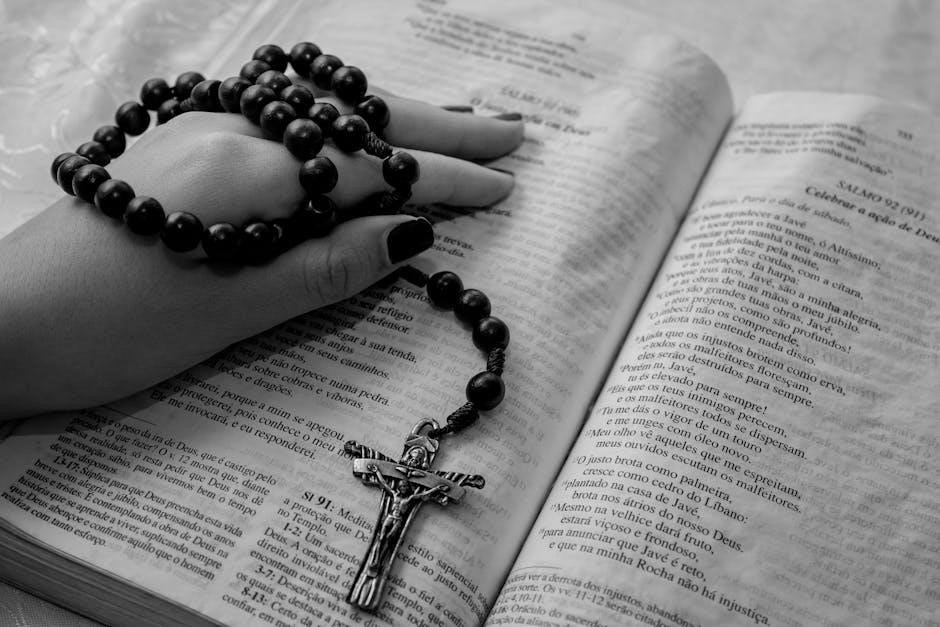

The Bible in a Year Reading Plan is a comprehensive 365-day program designed to guide readers through the entire Catholic Bible. Presented by Ascension, it offers a structured approach to understanding Scripture, blending daily readings with insightful commentary.

1.1 Overview of the Program

The Ascension Presents Bible in a Year Reading Plan is a meticulously structured 365-day program designed to guide readers through the entire Catholic Bible. Each day, participants engage with carefully selected passages from the Old Testament, New Testament, Psalms, and Proverbs, ensuring a balanced and immersive journey through Scripture. Hosted by Fr. Mike Schmitz, the program features daily readings and commentary, with each episode lasting approximately 20 minutes. This format makes it accessible for individuals to incorporate into their daily routines, whether during commutes, quiet reflection, or family time. The plan is inspired by Jeff Cavins’ groundbreaking Great Adventure Bible Timeline, which provides a chronological framework for understanding salvation history. The Bible in a Year Reading Plan is available as a free downloadable PDF, complementing the podcast and allowing listeners to follow along with ease. Its color-coded structure aligns with the podcast episodes, helping users track their progress seamlessly. Since its launch, the program has gained unprecedented popularity, achieving over 142 million downloads and 3.3 billion minutes of listening worldwide, solidifying its place as a transformative resource for spiritual growth.

Features of the Reading Plan

The Bible in a Year Reading Plan offers daily readings from the Old Testament, New Testament, Psalms, and Proverbs, ensuring a balanced and enriching experience. It is inspired by Jeff Cavins’ Great Adventure Bible Timeline, providing a structured journey through salvation history.

2.1 Structure and Daily Readings

The Bible in a Year Reading Plan is meticulously structured to guide readers through the entire Catholic Bible in 365 days. Each day features carefully selected readings from the Old Testament, New Testament, Psalms, and Proverbs, ensuring a balanced and comprehensive journey through Scripture. The plan is inspired by Jeff Cavins’ Great Adventure Bible Timeline, which divides the Bible into 12 periods of salvation history, helping readers understand the overarching narrative.

Daily readings are designed to be manageable, typically lasting about 20 minutes. They are led by Fr. Mike Schmitz, who provides engaging commentary, reflections, and prayers to deepen understanding and foster spiritual growth. The plan is available as a downloadable PDF, making it easy to follow along with the accompanying podcast or on its own. This structured approach ensures that participants stay on track and experience the richness of God’s Word throughout the year.

The Role of Ascension Presents

Ascension Presents is a Catholic media network dedicated to spreading the Gospel and fostering spiritual growth. They produce the Bible in a Year podcast and provide the accompanying PDF reading plan, offering a structured way to engage with Scripture daily. Their mission is to help people grow in faith through authentic encounters with Christ, making the Bible accessible to all.

3.1 About Ascension and Their Mission

Ascension is a Catholic media network dedicated to spreading the Gospel and fostering spiritual growth. Their mission revolves around creating engaging content that helps people encounter Christ and deepen their faith. Through podcasts, videos, and written resources, Ascension equips Catholics with tools for prayer, Scripture study, and sacramental life.

Central to their mission is making the Bible accessible to everyone. The Bible in a Year Reading Plan exemplifies this goal, providing a structured path for readers to traverse the entire Catholic Bible in 365 days. Ascension’s initiatives aim to bridge the gap between faith and daily life, ensuring that Scripture remains relevant and transformative.

By blending traditional Catholic teachings with modern media, Ascension reaches a wide audience, from lifelong Catholics to those exploring their faith. Their resources are designed to inspire reflection, prayer, and a deeper connection to God’s Word. The Bible in a Year program is a testament to Ascension’s commitment to helping people grow in their relationship with Christ through Scripture.

The Great Adventure Bible Timeline

The Great Adventure Bible Timeline, developed by Jeff Cavins, is a foundational framework organizing Scripture into a chronological narrative. It divides the Bible into 12 periods, helping readers understand the overarching story of salvation history and its relevance to their lives today.

4.1 Jeff Cavins’ Methodology

Jeff Cavins, a renowned Catholic Bible teacher, developed The Great Adventure Bible Timeline, a groundbreaking approach to understanding Scripture. His methodology emphasizes the importance of reading the Bible chronologically, dividing it into 12 distinct periods that reveal the overarching narrative of salvation history. By focusing on the “big picture,” Cavins helps readers connect the dots between the Old and New Testaments, seeing how every book and event points to God’s plan of redemption.

Cavins’ approach is designed to make the Bible accessible and engaging, avoiding the common frustration of feeling lost in a disjointed collection of stories. His system uses color-coding, timelines, and a structured framework to guide readers seamlessly through the entire Bible. This method not only deepens understanding but also fosters a love for Scripture, making it easier to apply its teachings to daily life. The Ascension Presents Bible in a Year Reading Plan incorporates Cavins’ timeline, ensuring participants experience the Bible as a unified and transformative story.

Host and Commentary

Father Mike Schmitz, a dynamic and engaging Catholic priest, hosts the Bible in a Year podcast. His daily commentary and reflections provide deeper insights into the Scriptures, making the Bible relatable and accessible for modern listeners. His approach combines theological expertise with a pastoral heart, fostering spiritual growth and connection.

5.1 Fr. Mike Schmitz and His Approach

Father Mike Schmitz, a Catholic priest known for his engaging and relatable style, leads listeners through the Bible in a Year journey. Each daily episode features Fr. Mike reading 2-3 passages, followed by insightful commentary and reflection. His approach is rooted in a deep understanding of Scripture, blending theological insights with practical applications for everyday life. Fr. Mike’s dynamic delivery and relatable examples make the Bible accessible to a wide audience, from newcomers to lifelong Catholics. By focusing on the narrative thread of salvation history, he helps listeners connect the dots between the Old and New Testaments, revealing the unity and coherence of God’s plan. His engaging storytelling and heartfelt reflections create a sense of companionship, making the journey through the entire Catholic Bible both manageable and enriching. Fr. Mike’s passion for Scripture is contagious, inspiring listeners to deepen their faith and integrate God’s Word into their daily lives.

Benefits of the Plan

The Bible in a Year plan fosters spiritual growth with accessible daily readings. It structures the entire Catholic Bible into manageable segments, covering Old Testament, New Testament, Psalms, and Proverbs, offering insightful commentary to inspire faith deeply.

6.1 Spiritual Growth and Accessibility

The Bible in a Year Reading Plan is designed to foster spiritual growth by guiding readers through the entire Catholic Bible in a structured and accessible manner. Each day, participants engage with carefully selected passages from the Old Testament, New Testament, Psalms, and Proverbs. This balanced approach ensures that readers gain a holistic understanding of Scripture, while Fr. Mike Schmitz’s commentary provides context and insights to deepen faith. The plan is accessible to everyone, regardless of prior Bible knowledge, making it ideal for both newcomers and seasoned believers.

The daily readings are concise yet meaningful, allowing even those with busy schedules to stay committed to the program. By following the plan, participants can develop a consistent habit of prayerful reading, leading to a stronger connection with God’s Word. The program’s accessibility and spiritual depth make it a powerful tool for personal faith formation and communal devotion.

How to Follow the Plan

To follow the Bible in a Year Reading Plan, download the free PDF from Ascension Press. Each day, read the assigned passages and listen to Fr. Mike Schmitz’s podcast for commentary. The plan is structured to guide you through the entire Bible in 365 days.

7.1 Steps to Get Started

Getting started with the Bible in a Year Reading Plan is simple and accessible. First, download the free PDF reading plan from Ascension Press, which outlines the daily Scripture passages. Next, choose a Catholic Bible version to use alongside the plan. You can also subscribe to the Bible in a Year podcast, hosted by Fr. Mike Schmitz, on platforms like Apple Podcasts, Spotify, or Google Podcasts. Each episode complements the daily readings with commentary and reflections. Set a consistent daily routine, such as reading in the morning or evening, to stay on track. Create a dedicated space for prayer and study to enhance your experience. Consider using a journal to record insights, prayers, or questions as you journey through the Bible. For added support, join a study group or share the experience with family and friends. Finally, commit to consistency and patience, allowing God’s Word to transform your life over the year. By following these steps, you’ll be well-prepared to embark on this spiritual journey and deepen your faith.

Reception and Impact

The Bible in a Year Reading Plan has achieved remarkable success, with over 142 million downloads and 3.3 billion minutes listened worldwide. It became the #1 podcast on Apple Podcasts shortly after its launch, reflecting its widespread appeal and spiritual impact on listeners.

8.1 Popularity and Listener Feedback

The Bible in a Year Reading Plan has garnered exceptional popularity, with over 142 million downloads and 3.3 billion minutes of listening worldwide. It quickly rose to the top of Apple Podcasts, becoming the #1 show shortly after its release. Listeners have praised the program for its structured approach and accessibility, making it easier for people of all faith levels to engage with Scripture.

Many listeners have shared how the plan has deepened their faith and provided a sense of community. The daily readings, combined with Fr. Mike Schmitz’s commentary, have been particularly appreciated for their clarity and relatability. The podcast’s success reflects a growing desire among Catholics and Christians to reconnect with the Bible in a meaningful way. Its impact is evident in the countless testimonials from listeners who credit the program with helping them understand and love God’s Word more profoundly.

FAQs

What is the Bible in a Year Reading Plan? It is a 365-day program guiding readers through the Catholic Bible, with daily readings and commentary by Fr. Mike Schmitz.

How can I access the plan? It is available as a free downloadable PDF from Ascension Press.

Is the plan suitable for everyone? Yes, it is designed to be accessible for Catholics of all ages and faith levels.

Where can I listen to the podcast? The podcast is available on major platforms like Apple Podcasts and Spotify.

How popular is the program? It has reached 142 million downloads and 3.3 billion minutes of listening worldwide.

9.1 Common Questions Answered

What is the Bible in a Year Reading Plan? It is a 365-day program designed to guide readers through the entire Catholic Bible, with daily readings and commentary by Fr. Mike Schmitz.

How can I access the reading plan? The plan is available as a free downloadable PDF from Ascension Press, and it can also be followed through the accompanying podcast.

Is the plan suitable for everyone? Yes, the program is designed to be accessible for Catholics of all ages and faith levels, making it ideal for both newcomers and those deeply familiar with Scripture.

What makes this plan unique? It follows a reading plan inspired by The Great Adventure Bible Timeline, developed by Jeff Cavins, which provides a structured and meaningful journey through salvation history.

Can I listen to the readings? Yes, the podcast is available on major platforms like Apple Podcasts and Spotify, with daily episodes lasting 18-20 minutes.

How popular is the program? The Bible in a Year has achieved remarkable success, with over 142 million downloads and 3.3 billion minutes of listening worldwide.

What Bible translation is used? The readings are based on the New International Version (NIV) of the Bible.

Is the plan available in other languages? Currently, the program is primarily in English, but translations may be considered based on demand.

Can I use this plan with my parish or group? Absolutely! Many groups and parishes use the plan for communal study and reflection.

What if I fall behind? The plan is flexible, and you can adjust your pace to catch up or continue at your own speed.

Are there additional resources available? Yes, Ascension Press offers complementary materials, such as study guides and prayer resources, to deepen your experience.